Tylenol Upcycled From Plastic

Air Date: Week of September 5, 2025

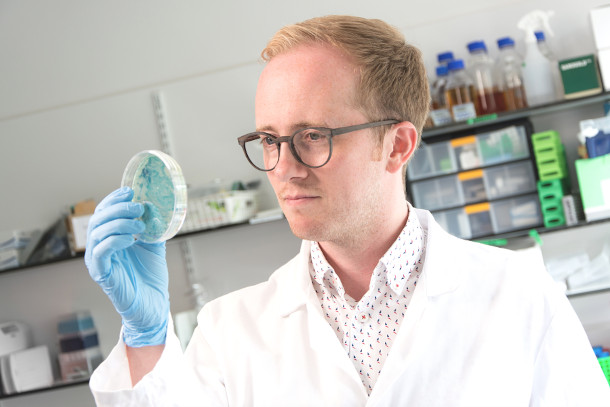

The strain of E. coli bacteria used in Dr. Wallace’s study is different from the strain that causes human disease. In fact, by genetically engineering it, Dr. Wallace’s team was able to use it to turn plastic waste into acetaminophen. (Photo: The University of Edinburgh)

Scientists in the UK were able to use genetically modified bacteria to turn plastic bottles into the common pain reliever acetaminophen, also known as paracetamol and Tylenol. Lead researcher Stephen Wallace, a Professor of Chemical Biotechnology at the University of Edinburgh, speaks with Host Jenni Doering about the potential applications of this biotech breakthrough.

Transcript

DOERING: As the planet becomes overwhelmed by plastic waste, some researchers are using creative chemistry and biology to come up with possible solutions. Scientists in the UK recently published a paper in the journal Nature Chemistry describing how they turned plastic bottles into the common pain reliever Tylenol, also known as acetaminophen or paracetamol. Their tiny comrades in this remarkable transformation were genetically modified E. coli bacteria. Every plastic bottle could be turned into two acetaminophen pills. What’s more, one of the genes that enabled those bacteria to make Tylenol came from mushrooms! Thanks to advances in DNA editing technology, researchers were able to insert this mushroom gene into the bacterial genome. With us today is Stephen Wallace, the lead author on the paper and a Professor of Chemical Biotechnology at the University of Edinburgh. Hi Stephen, and welcome to Living on Earth!

WALLACE: Hey, Jenni, thanks for having me.

DOERING: So you feed E. coli plastic. Well, there's a long process, but you feed E. coli plastic, it eventually produces Tylenol. What is left over from that process? I mean, you know, usually chemistry and biology aren't 100% efficient.

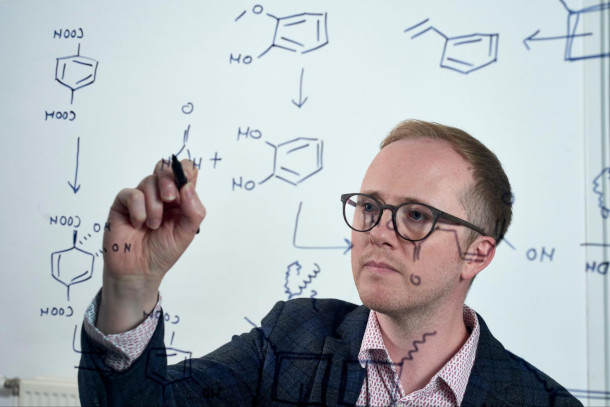

Here Dr. Wallace monitors the growth of the bacteria. He’ll eventually feed the bacteria a soup of broken down PET plastic, a common form of plastic used in bottles and food packaging. (Photo: The University of Edinburgh)

WALLACE: Yeah, exactly. So first of all, we have to take the plastic. And we took a waste plastic bottle, in this example, just one that we that we found on the streets on the way to lab one morning, and we deconstruct that or depolymerize that using established chemical methods, which basically take the polymer and release its chemical monomers, or the building blocks of that polymer. And those building blocks for polyethylene terephthalate, or PET plastic, which is the plastic we focused the study on, is two molecules. The first is called terephthalic acids, and the second is called ethylene glycol. And there are very many different uses for ethylene glycol in the industry. And we focus, in this instance, on the use of terephthalic acid, that other monomer that comes from deconstructed plastic. So it creates sort of like a plastic soup, if you like, which we then feed to the bacterium. And they take one part of that and transform that into Tylenol, but they leave that ethylene glycol alone. So that is one of the other things that comes from the process that can be used in other sort of industrial situations.

DOERING: And by the way, you mentioned this like P-E-T, PET plastic. What kind of plastic is that?

WALLACE: So PET is probably one of the most widespread plastics that's used throughout modern day society. It's a very rigid, very durable synthetic material that's used to make things like plastic bottles or sort of the films you get on top of salads and sandwiches and in the supermarkets. It's designed to be very robust, but because of that reason, when it's either sent to a landfill or it's unfortunately sometimes ends up in the environment or in the ocean, it's very resistant to degradation, and that's what causes it to accumulate and causes all those pollution issues that we widely associate with the plastic waste crisis currently.

DOERING: So let's zoom out to the bigger picture. A lot of pharmaceuticals actually come from fossil fuels, which is part of why this process is even possible. But just how much of our medicine comes from fossil fuels?

WALLACE: Yeah, this is something that absolutely fascinates me, and has been a really interesting point that's come from this research. I think just it really astounds me as a scientist, that people don't realize that the majority of the medication they take every day comes from fossil fuels. It's a refined petrochemical. It's the exact same material that you put in your car. I think it's 60 to 70% of all of the medication that we rely on to treat disease currently are reliant on this natural feedstock, fossil fuels. And the real issue with that is two things. The first is fossil fuels are not a limitless resource from which we can make these medications from. In fact, they're running out at quite an alarming rate, and the industrial processes that we use to transform fossil fuels into modern day medications are hugely polluting into the environment. So by taking this technology and programming bacteria to do this in a much more sort of milder, much greener way, much more eco friendly way, we not only defossilize the manufacture of this worldwide essential medication in a way that doesn't damage the environment or release climate emissions, but we also clean up plastic waste from the environment at the same time.

DOERING: By the way, why use biology and not just chemistry to do this?

Though the process isn’t nearly ready for an industrial scale production, Dr. Wallace hopes that in the future consumers will have the opportunity to buy acetaminophen not derived from fossil fuels but rather from plastic waste. (Photo: The University of Edinburgh)

WALLACE: Yeah, that's a really interesting question, actually. Certainly, to depolymerize plastic, you can use chemistry to do that. You can also use biology, but typically, bio-based processes operate at very low temperatures. They operate in very sort of mild water-based reactions. Whereas chemical methods, you typically need much more energy input to heat these reactions up. They tend to use, you know, petrochemical based solvents as well, to try and help these reactions go faster, and catalysts as well. So I think the bio-based processes are on the whole a lot milder and use a lot less energy, and are better for the environment themselves. But to make paracetamol from or Tylenol from plastic bottles, you cannot do that. It's impossible using chemistry alone, and it has to be done using biology.

DOERING: And by the way, paracetamol is just a different name for acetaminophen, or Tylenol. Is that right?

WALLACE: Yeah, of course. Sorry, it's my Britishism. That's absolutely the brand's name that which we sell acetaminophen under. It's the same as Tylenol. Absolutely.

DOERING: I'm going to play devil's advocate for a second. This research isn't nearly advanced enough to be scaled up anytime soon. So you know, how optimistic should we be that one day, most of our acetaminophen, our Tylenol, comes from plastic bottles?

WALLACE: Yeah, that's a really great question, actually. And I think it's really important to emphasize, we're an academic discovery lab. This is a very early stage project, a very early discovery proof of concept project that has shown that this is actually feasible. The next steps for this is absolutely to try and see whether we can scale this up to make really large quantities of paracetamol from existing plastic waste. And we're working with industry, both in the UK and the world around the world now to try and see whether this could be commercially feasible in the future.

DOERING: So, what's next for you as a researcher?

WALLACE: Yeah, this, this project has been wonderful, and it's been a real labor of love for many, many years up to this point, but it really does feel like the starting point for both this and the wider field of engineering biology. Because, you know, if we can program bacteria using this technology to turn plastic waste into Tylenol, imagine what else we can do, right? But more broadly than that, waste is just carbon, and microbes love carbon, so we've been examining all different types of weird and wonderful wastes and thinking, okay, you know, how can we program biology to turn this into something that's a bit more exciting than simply landfill or waste that goes to incineration? We published a piece of work a couple of months ago where we examined fatberg waste from the sewers in London. And these are sort of greasy deposits that block the sewers underground. And we did a chemical analysis of these, and it turns out they're really rich in organic small molecules, so tons and tons of carbon, literally. So we designed some bacteria that could eat these fatbergs from the sewers and turn them into fragrance compounds that you could wear. And we're currently working with a Swiss fragrance manufacturer to try and see whether we can take sewer waste and turn them into fragrances that you will buy potentially in the future. So this idea of waste is just carbon and biology can be engineered to turn that into a whole variety of different products. It really does feel like this is the sort of creative beginning of something really quite exciting.

The vast majority of our waste is simply carbon molecules. And since microorganisms love carbon, Dr. Wallace envisions a future where we could use microbes to turn a whole range of wastes into new products rather than relying on our dwindling fossil fuel reserves. (Photo: The University of Edinburgh)

DOERING: Wow. My head is spinning at the transformation that, that, that is quite some upcycling there of fatberg waste to perfume.

WALLACE: Yeah, exactly. So would you, would you wear perfume that came from fatberg waste?

DOERING: I'd have to smell it first. But hey, it's, it's just carbon, right?

WALLACE: It's just carbon. Exactly. If we can wear perfume that comes from oil, or if we can take medicine that comes from oil, why not from fatbergs? Why not from plastic bottles? Absolutely.

DOERING: Stephen Wallace is the lead author on the paper and a Professor of chemical biotechnology at the University of Edinburgh in the UK. Thank you so much, Dr. Wallace.

WALLACE: Thank you, Jenni, it's been a pleasure to be here. Thanks.

Links

Read Dr. Stephen Wallace’s original study

Living on Earth wants to hear from you!

Living on Earth

62 Calef Highway, Suite 212

Lee, NH 03861

Telephone: 617-287-4121

E-mail: comments@loe.org

Newsletter [Click here]

Donate to Living on Earth!

Living on Earth is an independent media program and relies entirely on contributions from listeners and institutions supporting public service. Please donate now to preserve an independent environmental voice.

NewsletterLiving on Earth offers a weekly delivery of the show's rundown to your mailbox. Sign up for our newsletter today!

Sailors For The Sea: Be the change you want to sea.

Sailors For The Sea: Be the change you want to sea.

The Grantham Foundation for the Protection of the Environment: Committed to protecting and improving the health of the global environment.

The Grantham Foundation for the Protection of the Environment: Committed to protecting and improving the health of the global environment.

Contribute to Living on Earth and receive, as our gift to you, an archival print of one of Mark Seth Lender's extraordinary wildlife photographs. Follow the link to see Mark's current collection of photographs.

Contribute to Living on Earth and receive, as our gift to you, an archival print of one of Mark Seth Lender's extraordinary wildlife photographs. Follow the link to see Mark's current collection of photographs.

Buy a signed copy of Mark Seth Lender's book Smeagull the Seagull & support Living on Earth

Buy a signed copy of Mark Seth Lender's book Smeagull the Seagull & support Living on Earth